The Problem

-

Context: The “Creator Warehouse” team (merch team) is in a separate building from the main studio.

-

Current Setup: They were using a Ubiquiti AirFiber XG wireless dish setup.

-

Issues:

-

The dishes were mounted too low, causing signal interference from buildings, limiting speeds to ~1/6th of the theoretical max.

-

While relatively stable, the proper solution for a permanent business connection is a hardwired line.

-

-

Goal: Connect the two buildings using a physical cable without paying for a second commercial internet subscription.

The Solution: Bi-Directional Fiber

-

Infrastructure Discovery: They found an existing conduit running between the main electrical room and the Creator Warehouse building.

-

The Constraint: The main fiber cable entering the complex belongs to the ISP. It has 12 strands, but Linus Media Group only pays for/uses 2 of them (one for send, one for receive).

-

The “Hack”: Instead of running a brand new cable through the potentially full conduit or using the ISP’s dark fiber (which they don’t own), they decided to free up one of their own existing fiber strands.

-

Bi-Directional Transceivers: By using special SFP28 transceivers, they can transmit and receive data on a single strand of fiber using two different wavelengths (1270nm and 1330nm).

-

Result: This frees up the second strand of their existing duplex pair to be used as a dedicated line to the other building.

-

The Installation Process

-

The “Outage”: To install the new transceivers, they had to briefly disconnect the main studio’s internet. They switched to a backup connection, but it disrupted some remote workflows.

-

Transceiver Swap:

-

They replaced the standard duplex transceivers with the new bi-directional ones.

-

Crucial Detail: Bi-directional transceivers must be paired oppositely (e.g., Side A transmits on 1270nm/receives on 1330nm, Side B must transmit on 1330nm/receive on 1270nm).

-

-

Running the New Cable:

-

They had to pull a new fiber cable through a conduit found under a sink in the Creator Warehouse building.

-

The Struggle: The pull was difficult because they didn’t use lubricant initially, and the cable got tangled. They eventually succeeded by using hand soap as a makeshift lubricant.

-

Final Setup & Testing

-

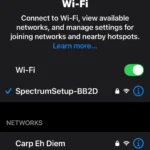

Hardware: They installed a Ubiquiti UniFi Enterprise XG 24 switch in the Creator Warehouse to handle the 25-gigabit connection.

-

Troubleshooting: The 25-gig link initially didn’t work until they adjusted the “Forward Error Correction” (FEC) settings on the Dell switch to “CL74” mode.

-

Speed Test:

-

Internet: Achieving near 10Gbps (limited by the speed test server/ISP connection).

-

Local Transfer (NAS): Transfer speeds were around 800 MB/s (megabytes per second), limited by the SMB protocol and single-core CPU performance, not the fiber link itself .

-

Conclusion

-

The upgrade provided a massive speed increase (roughly 7-8x faster than the wireless bridge) and immune to weather interference.

-

They decided to keep the old wireless dishes as a backup connection